Coring and sampling in nuclear environments

We design special machines for taking radioactive samples

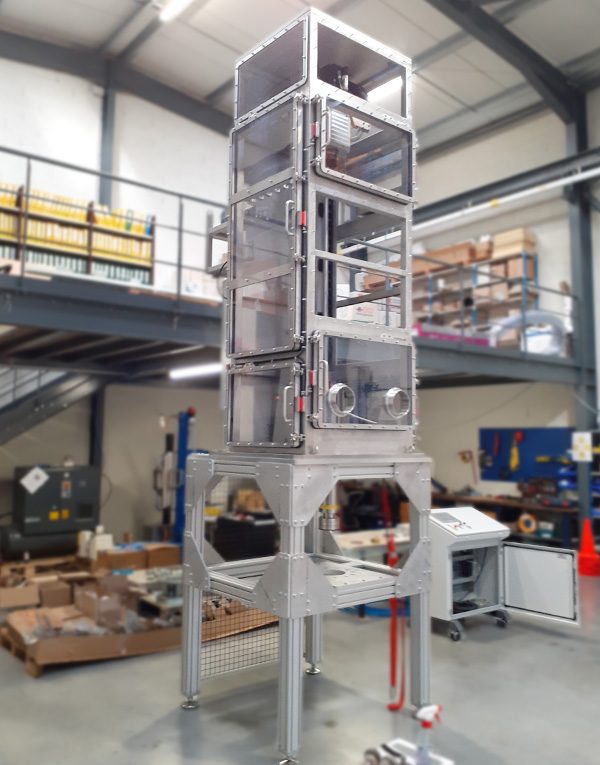

Coring/sampling machine

Coring and sampling in nuclear environments

We design special machines for taking radioactive samples

Coring/sampling machine

Coring and sampling in nuclear environments

We design special machines for taking radioactive samples